When a building shows signs of water damage, waterproofing membranes can provide an easy and cost-effective fix. Waterproofing has different variables and steps to ensure the best integrity and longevity for your building and the people inside. Unfortunately, failures within the waterproofing membrane can have a disastrous effect on the integrity of your building’s structure, lead to health risks for building occupants, and increase total cost of ownership. Meanwhile, having knowledge of the types of membranes, application methods, and how to choose a service provider can make the process even easier. Let’s take an in-depth look at these key things to know about waterproofing membranes, including:

- The fundamentals of waterproofing membranes, the value in the modern building.

- The value of waterproofing membranes in maintaining your assets.

- The differences between various membrane materials, including chemical vs physical, sheet membranes.

- How to approach selecting a membrane material and a few best practices for ensuring its proper application.

I. What Are Waterproofing Membranes?

A waterproofing membrane is a layer of water-tight material that lies on a surface to prevent water leaks or damages. The process usually consists of liquid-applied or pre-formed sheet membranes. According to Chris Rupkey, chief economist at MUFG in New York, “The global waterproofing membrane market size is set to gain momentum from the increasing investments by renowned companies in the development of eco-friendly products for green buildings, as conventional membranes can cause harm to the environment by releasing toxic chemicals. The report further states that the market stood at USD 27.17 billion in 2020. It is projected to grow from USD 28.05 billion in 2021 to USD 42.85 billion in 2028 at a CAGR of 6.2% during the forecast period.”

II. Why Is It Important?

The objective of waterproofing is to secure a building from all kinds of water damages and prevent further repair work on the structure. Excess water exposure can enlarge the foundation cracks and joints, leading to issues with leakage, deterioration, and spalling that will require repairs. Before water damage leads to bigger issues in a building, waterproofing can provide:

- Safety: Damage due to a lack of waterproofing can be so severe that it impacts the integrity of the building, resulting in an unsafe environment.

- A way to strengthen the structure: Waterproofing membranes prolong the lifespan of a building by limiting any moisture that may intrude and cause rust, rotting, corrosion, structural defects, or other damage to property and contents.

- A healthier environment: Waterproofing can help provide a space that is well-maintained and protected from different elements. The buildup on the walls and ceilings can cause fungus and mold growth, leading to allergies and health issues.

- A way to reduce maintenance costs and increase property value: Quality waterproofing — done right the first time — will safeguard property from water damage and limit the need for costly repairs or maintenance services.

Fixing water damage before it becomes a greater issue is extremely important. As further explained in relation to the movements of air within materials, Energy Saver said “air movement accounts for more than 98% of all water vapor movement in building cavities. Air naturally moves from high-pressure areas to lower pressure areas by the easiest path available — generally through any available hole or crack in the building envelope. Moisture transfer by air currents happens quickly, and carefully and permanently air sealing any unintended paths for air movement in and out of the house is a very effective moisture control strategy.” Waterproofing can fill the paths for such air movements and stop water vapor from causing more harm to the building structure. This is particularly vital in terms of keeping building occupants safe from airborne pathogens.

As the CDC explains: “Molds are very common in buildings and homes. Mold will grow in places with a lot of moisture, such as around leaks in roofs, windows, or pipes, or where there has been flooding. Mold grows well on paper products, cardboard, ceiling tiles, and wood products. Mold can also grow in dust, paints, wallpaper, insulation, drywall, carpet, fabric, and upholstery. The most common indoor molds are Cladosporium, Penicillium, and Aspergillus. We do not have precise information about how often different molds are found in buildings and homes.”

Considering that many of these materials are basic construction materials, any water entry, even in vapor form (such as humidity), could lead to an added risk of mold growth. In the case of commercial buildings, such factors essentially open your business to the liability of illnesses associated with these pathogens. Furthermore, the CDC notes how there is evidence to suggest that deterioration of work and living environments due to mold spore exposure can lead to memory loss, lethargy, and more. And in commercial buildings, this amounts to less productive workers and even worsening customer experiences. It’s for these reasons that a proper waterproofing envelope protects against water in any phase, whether liquid, solid (ice) or gas (humidity), is critical.

III. The Difference Between the Membranes & Key Aspects to Selecting a Waterproofing Membrane Type.

Different buildings will require different types of waterproofing membranes to ensure no water damage will continue. Waterproofing membranes can help protect any building; basement or roof membranes can help prevent water damage from happening. This long-term decision can save building structures from potentially costly consequences such as joint problems and cracking. Moreover, the type of membrane may either be chemical and liquid upon application or be made up of multiple layers of prefabricated sheet membranes.

As further noted by Raja Haria via LinkedIn: “Liquid Applied Waterproofing is a process of waterproofing application using special liquid. It’s used for roofs like flat roofs, pitched roofs, domed roofs and walls also. A liquid applied membrane involves Fully bonded monolithic coating application. This coating, once cured, forms a rubber-like elastomeric waterproofing membrane. Liquid applied membranes are flexible enough to take any shape they are laid to, also they have properties like strength, tear resistance, weathering resistance, UV stability & elasticity to bridge the cracks developed underneath the surface.”

Of course, that only begins to scratch the surface of the true scale and variety within waterproofing membrane options.

The different types of waterproofing membranes consist of the following primary materials.

1. Self-Adhesive Modified Bituminous Membrane

Self-adhesive modified bituminous membranes are composed of asphalt, polymers, and tackifiers, and may contain mineral stabilizers. The product may be reinforced with fiberglass, polyester, or a combination of the two. Products designed for exposure to the elements typically will be surfaced with mineral granules, coatings, films, or other opaque surfacing.

2. Polymer-Modified Bitumen Membrane

The most widespread materials for the creation of the waterproofing layer are the polymer-bitumen roll-fed sheet membranes. These materials could also be used as an underlay for pitched roofs and as a vapor barrier.

3. EPDM Membrane

It is a preformed elastomeric waterproofing membrane made of high-quality EPDM rubber. It exhibits high tensile strength, elongation, tear strength, and resistance to weathering, heat aging, ozone, UV rays, acids, alkalis, and oxygenated solvents.

4. Thermoplastic Membrane

Thermoplastic roof membranes are distinct from other commercial roofing systems. It is a blend of polypropylene, ethylene-propylene and is often reinforced with polyester. Sheets of TPO can contain UV absorbers, colorants, flame retardants, or other add-ins to achieve the required physical properties.

5. Bituminous Membrane (Asphalt)

Hot melt liquid bituminous rubber blend structural waterproofing systems with an interlaid reinforcement can be used in roof and podium deck applications to provide a seamless waterproofing membrane for high green roofs and podiums, and are sometimes specified for winter applications where low temperatures are common.

6. Polyurethane Membrane

These products come with a fiber-enhanced, water-based polyurethane membrane that has been designed for a range of waterproofing applications where the membrane is to be covered with tiles, screeds, concrete beds, and more. These membranes offer excellent adhesion properties for use on building substrates, including concrete, masonry, renders, cement sheeting, wet area sheet surfaces, and plasterboard surfaces.

7. Chemical Grouting to Seal Cement Structures

Hydrophilic chemical grouts have flexibility and resilience after full cure. This will allow movement to occur in the structure without damaging the seal. Hydrophobic resins are rigid after curing and do not recover from compression. If the structure moves, there is a good chance the cell structure will be damaged and leaks will reappear. Hydrophobic chemical grout is low viscosity and permeates loose and non-consolidated soils readily.

IV. Application Process for Waterproofing Membranes

Regardless of the scale, size, location, or type of building, waterproofing membranes provide an essential component to protect the structural integrity of a building. The longer a leak is allowed to progress unchecked, the more extensive the underlying deterioration can become. Stopping a minor leak is far easier than rehabilitating the damage resulting from a major one.

Thorough Inspection of the Materials Used and Prior Membranes

Noting how the building responds to weather events and temperature fluctuations can affect the building materials used. Inspect the prior membrane used and see how the weather affected it or what problems continued to happen. Then, form a game plan to determine which type of membrane to use.

Cleaning of the Area

Preparation requirements vary by the type of material used and the application methods. Make sure the surface and materials are well-prepared and ready for membrane application. Cleaning provides for good adhesion to the substrate. Also, the manufacturer’s guidelines include instructions for cleaning the substrate to remove dirt, debris, and other surface contaminants.

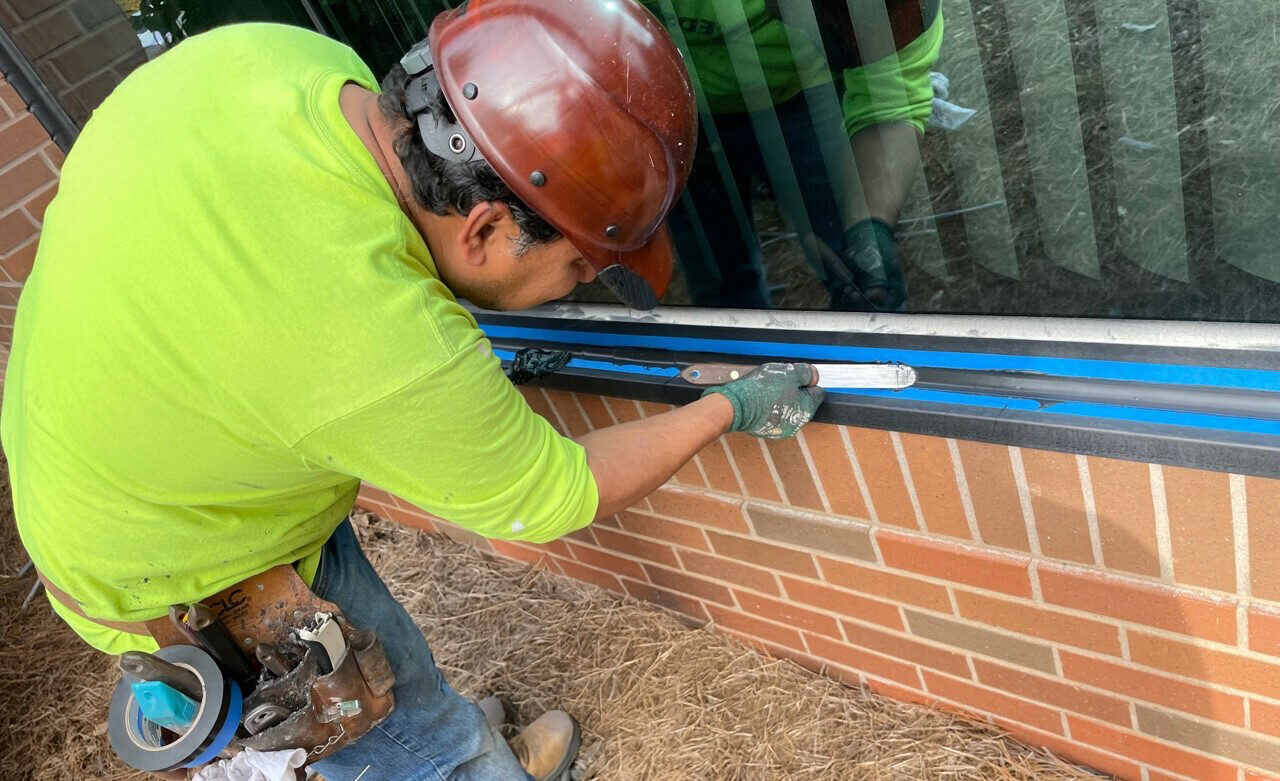

Application of the Chosen Material

Waterproofing membranes generally consist of liquid applied or preformed sheets. Liquid-applied membranes must have the correct thickness or installation errors will occur. For sheet membranes, joints between sheets are critical and must have a perfect application to avoid leakage.

Complications to Watch for During the Application Process

If any complications pop up during the waterproofing process, the membrane will not work properly and therefore will not solve the leakage. A few examples of installation errors to look for:

- Poor workmanship can result in improper application or the wrong waterproofing membrane being used. confusing

- Excessive thickness may result in re-emulsification and splitting while the membrane cures.

- Uneven film thickness during the application process, thicker coats restrict movement and thinner coats can result in tears under minimal movement.

- Coating materials must be abrasive, resistant, and accommodate the building movement. Any thin spots, weak points, or high spots can result in excessive wear, forming ruptures and blisters.

- If the waterproofing is applied prior to the completion of the structural elements, it may prompt negative effects such as deflections or other imperfections in the waterproofing.

Destructive Testing to Ensure Its Integrity

Destructive testing can confirm a successful installation and determine if water leaks will continue to cause issues. This is the literal process of attempting to remove the material, apply water to it, and rigorously ensure the seal is working properly.

Routine Maintenance & Inspection to Keep It in Tip-Top Shape

Keeping up with maintenance can prevent damages from happening again and once again verify that the installation was done correctly. In other words, maintenance and inspection are critical. And checking for signs of installation failure can save the building from costly future repairs. No crack, stain, or visual cue should go without proper inspection to make sure water damage has not come back.

V. After Application and The Role of Inspection in Maintaining the Membrane

After waterproofing takes place, certain steps can prevent recurring water damage and will not require further work. Closely monitoring the building and inspecting the membrane can ensure the water leak has stopped.

Constantly monitoring the membranes and looking for future signs of leakage can prevent the need for replacements. Pay close attention to signs that may indicate deterioration of the waterproofing membrane, such as staining and cracks; most problems have visual cues when water damage happens.

VI. How to Select a Waterproofing Service Provider

Effective waterproofing requires an action plan designed to preserve the structural integrity of a building while being cost-effective at the same time. Finding the right professional with the proper expertise will help ensure the job gets done right the first time. Here are some things to consider when selecting a waterproofing contractor:

Company History

A reputable waterproofing service should have an established, verifiable history of satisfied clients. This can help prospective customers learn the expertise level of the company while also checking references or reviews. When checking references, ask about the company’s services, their level of professionalism, the quality of the work, and the availability of follow-up support once the job was complete.

Awards & Certificates

This can show companies that excel in the industry and showcase the talent and ability to provide quality customer service. This can also go back to the company history and show the service goes above and beyond the bare minimum.

Licensed and Bonded

Make sure the company has proper licensing for the area and has the correct liability insurance. Many of the warranties on the products used by waterproofing companies may cancel out if not installed by a certified professional waterproofing contractor.

Written Contracts

Contracts can protect the customer and the contractor. Every contract should provide details of the proposed work, an estimate for the time it will take to perform the job, and the estimated cost. Before the job begins, ensure any guarantees and warranties have been documented in writing.

Prioritizes Safety

The contractor should take the proper steps to ensure the safety of their team, the customer and the property itself. The equipment and machines needed for waterproofing require skill to operate and come with a level of risk. Choosing a waterproofing team that prioritizes safety should always be of great importance, and doing so can prevent delays, mistakes, and unnecessary costs.

Offers Inspection Services

A professional contractor should have the option of conducting an inspection whenever water damage becomes apparent. A skilled waterproofing company should have the knowledge to pinpoint the source of the water and take the appropriate action to resolve the issue. Having the proper skill set is essential to ensuring that the issue can be resolved whether from the interior or exterior of the building.

Understands the Various Waterproofing Materials

Some of the more common signs of water damage in a building are more obvious. These include peeling paint, damp spots on basement walls, and rust on tools or appliances. However, some less obvious signs may be harder to identify such as cracks in walls, an unusual odor, or the presence of a chalky white substance on the walls. Choose a contractor that knows how to carefully inspect the entire area in order to address potential problems and know the proper solution.

Guarantees: Will Repair the Membrane If It Fails Prematurely

Ensure the contractor will come back if additional membrane service is needed. This will save the customer from having to pay a second time when the first service should have worked. Having this claim in writing can make sure the contractor will hold up their end of the bargain if the time comes.

The Big Picture: Waterproofing Is Vital to Your Business and Building Integrity

To save a commercial building from water leaks and damages while ensuring maximum integrity, waterproofing can provide the best answer. According to RJ Lometa of Vents Magazine, “Lack of waterproofing measures leads to increased risks in building integrity! Today, many urban construction projects are adversely affected because of this. Often building structural failures are an off-shoot of weak waterproofing measures.” The presentation and integrity of a building hold just as much value as the people in it.

Ensure the Best Waterproofing Service Provided

Keeping up with the maintenance of a building can add stress to any manager or employee. Waterproofing helps building managers stay a step ahead of the mess. To prevent future damage and improve the integrity of your building’s waterproof envelope, contact Valcourt.